Digitize and unify industrial process information in real time, boosting efficiency, productivity, and smart decision-making.

Industrial platform for monitoring, traceability, and continuous improvement based on operational data.

Boost your plant with intelligent data

telog is a platform for acquiring, recording, and analyzing industrial data.

Real-time data

Information available online and in real time.

Easy access

Information available from any web browser.

Full compatibility

Non-invasive and compatible with any process and sensor.

AI integration

Allows the use of artificial intelligence tools.

Smart industrial digitization

All your processes in a single platform

telog is more than just data logging

It turns them into smart decisions to optimize your plant.

These are some of its most valued capabilities according to our clients:

- Remote monitoring from anywherewithout restrictions on users or devices. Access to the platform starts with a monthly subscription.

- Customizable visualization without technical knowledge.

- Continuous, unlimited, and secure recording in the cloud.

- Predictive analysis and smart maintenance: Processing of historical data and trends to detect anomalies and optimize decision-making.

- Modular scalability with the ability to grow from a single machine to multiple lines or plants. without changing systems.

- Configurable alerts with notifications via Telegram, email, or SMS to anticipate failures or operational deviations.

- Compatible with existing sensors, processes, and control systems, without requiring new infrastructure.

- Ready-to-use reports without the need to export or manually process the data.

A modular ecosystem to adapt to each productive need.

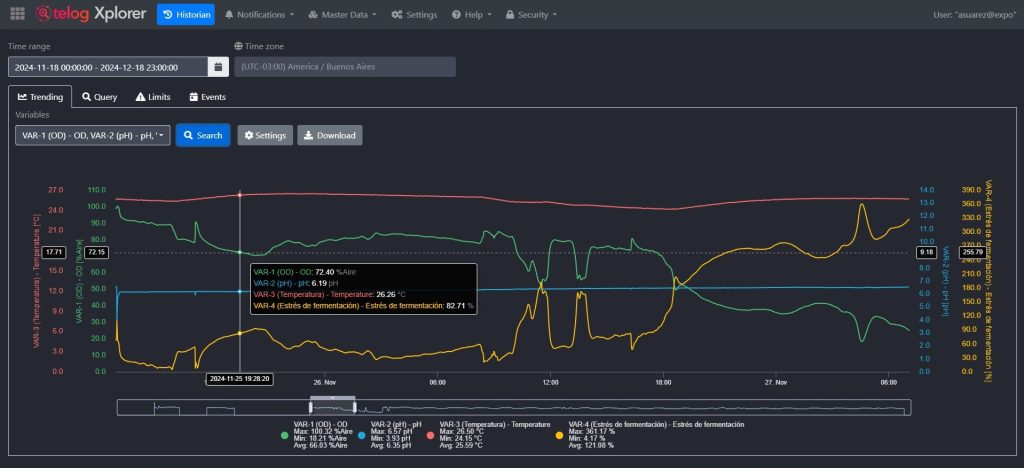

telog Xplorer:

Application for data exploration of variables uploaded to the platform. It allows the use of basic functionalities and also performs calculations to generate artificial variables.

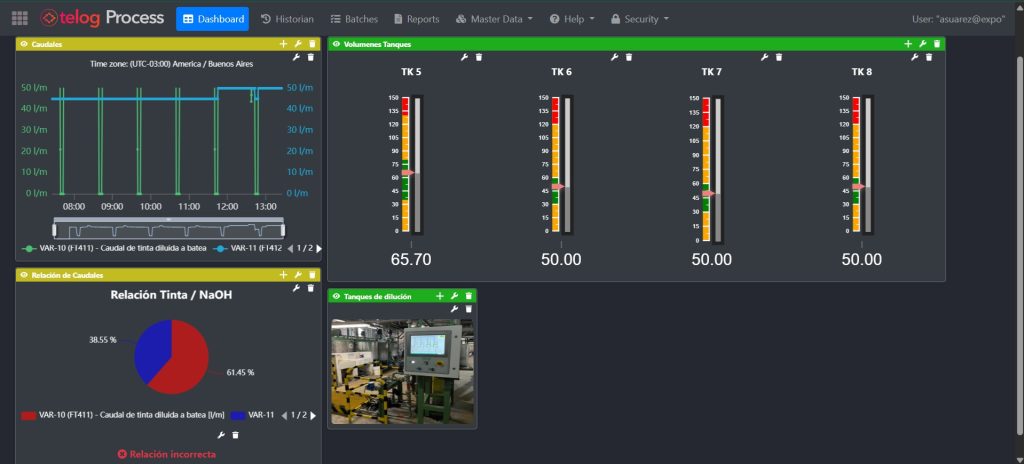

telog Process:

Application for process data exploration. It allows variables to be grouped by batches and equipment, visualize them in real time on a dynamic dashboard customizable by the user, and generate automatic email reports when the batch is completed.

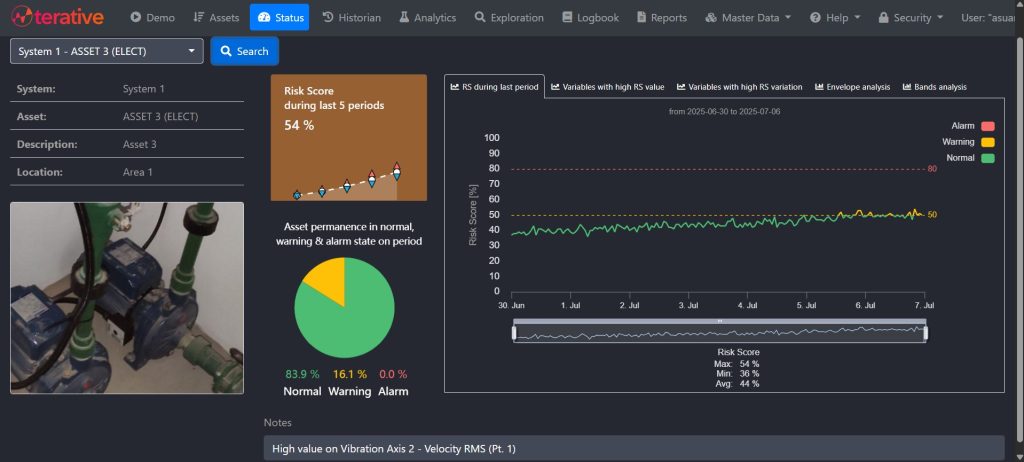

telog Terative:

Predictive maintenance application for industrial assets based on the analysis of measurements from various variables and the use of Artificial Intelligence algorithms. It allows interactive visualization of asset conditions and frequency spectra.

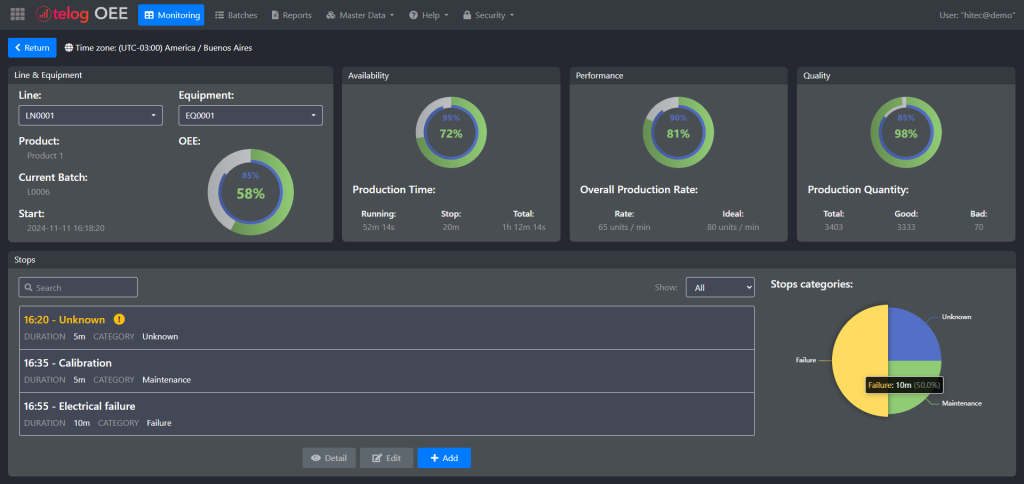

telog OEE:

Application for production optimization. It allows viewing productivity metrics for lines and equipment, as well as details of the current status, batches in progress, and recorded stoppages.

telog Energy

Application for energy consumption optimization. It allows real-time monitoring of energy use across all your devices and areas, identifying the highest consumption points through dynamic charts and detailed reports.

COMING SOON

telog SPC

Application for statistical process control. It allows monitoring the variability of critical variables, detecting trends and deviations in real time, and ensuring product repeatability and quality through control charts and performance analysis.

COMING SOON

telog connects to the process without modifying existing systems: it receives data from sensors, PLCs, or electrical signals, processes them, and uploads them to the cloud for real-time visualization from any device.

Operational efficiency with measurable return

The implementation of telog generates direct economic improvements on the plant through:

Elimination of plant rounds and manual records

Reduction of errors and rework due to undetected deviations

Increased production through bottleneck detection

Energy savings through the analysis of specific consumption

Reduction of unplanned stoppages due to unexpected failures

Optimization of maintenance by relying on actual process conditions

Facilitation of audits and reduction of costs due to non-conformities

Contact information

Adress

Condarco 931

Buenos Aires, Argentina

- info@telog.com.ar

Phone

- +54 11 5274-0868